Cognitive diagnostic system

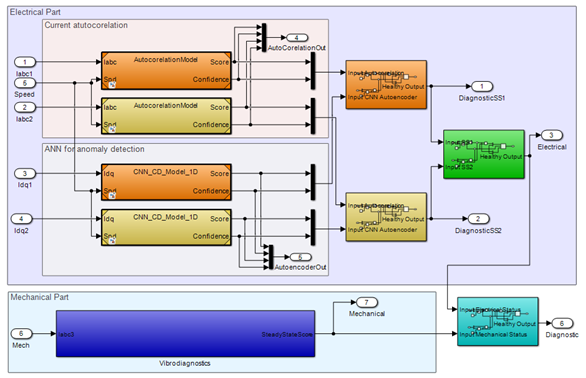

The Cognitive Diagnostic System (CDS) is an adaptive and modular diagnostic platform that combines traditional signal processing methods with AI algorithms to detect powertrain faults in real-time.

CDS uses both electrical and mechanical quantities to overcome the limitations of each approach. Electrical parameters allow rapid detection of severe faults, while mechanical signals help identify less obvious faults or faults occurring at low speeds that are difficult to detect using electrical quantities alone.

The system is divided into modules, which allow different approaches to be combined - from basic statistical methods to AI-based techniques, including neural networks and autoencoders. Each module is required not only to provide information about the condition of the powertrain but also to evaluate the reliability of its output based on the current operating point. The diagnostic system then combines the outputs from each module to provide a comprehensive diagnosis of either a specific part of the powertrain (in the case of n-times three-phase system) or the entire powertrain.

A key feature of CDS is its modularity and scalability, which allows easy addition of new diagnostic blocks and quick adaptation to new target powertrains. This feature also optimizes computing resources by enabling modules to operate independently on different processing cores.

The result is a comprehensive powertrain diagnostic that dynamically integrates multiple methods and reliably detects various anomalies in powertrain behavior.

The CDS was tested on a dual three-phase motor. The first part of the CDS was integrated into the parallel processing unit. In contrast, the second part of the CDS, which combines results, utilizes one core of the 3rd generation of AURIX microcontroller.